After the coffee harvest, coffee cherries are placed in a water bath. Overripe and defective cherries have a lower density than ripe yellow/red and unripe green cherries. That's why they swim on the surface of the water. We call them floaters. They are also joined by the branches and leaves that can be found in the harvest. The unripe and ripe intact fruits sink to the bottom of the water bath and are therefore called sinkers in technical language.

Then it gets down to business.

- I would like to know more about natural preparation

- I'm interested in the washed preparation

- I'm interested in Pulped Natural

- I would like to read more about honey processing

The classics of coffee preparation: Natural, Washed and Honey

Coffee cherries in Ethiopia. Philip Weller visited many Washing Stations there in 2024. Do you already know which processing method this is?

The further processing of coffee cherries is a science in itself. There are always innovations and new, sophisticated methods for processing, but let's start with the traditional ones: Natural, Washed, Pulped Natural and Honey.

They all differ in their approach and have a significant influence on the taste of a coffee.

Coffee cherries are further processed at a coffee washing station. After harvesting, the fruits with the popular seed that we know as coffee beans must be processed within 8 hours, otherwise there is a risk of rot. Larger farms have the necessary equipment on site and therefore operate their own washing stations. For farmers with small businesses, the investments required are too large. They bring their harvest to washing stations in their area.

The coffee washing stations are usually centrally located, e.g. in the next village or town. Machines are available here to wash, sort, ferment, depulp and dry the cherries - depending on which form of preparation is most suitable and desired by the green coffee customers.

What is natural coffee?

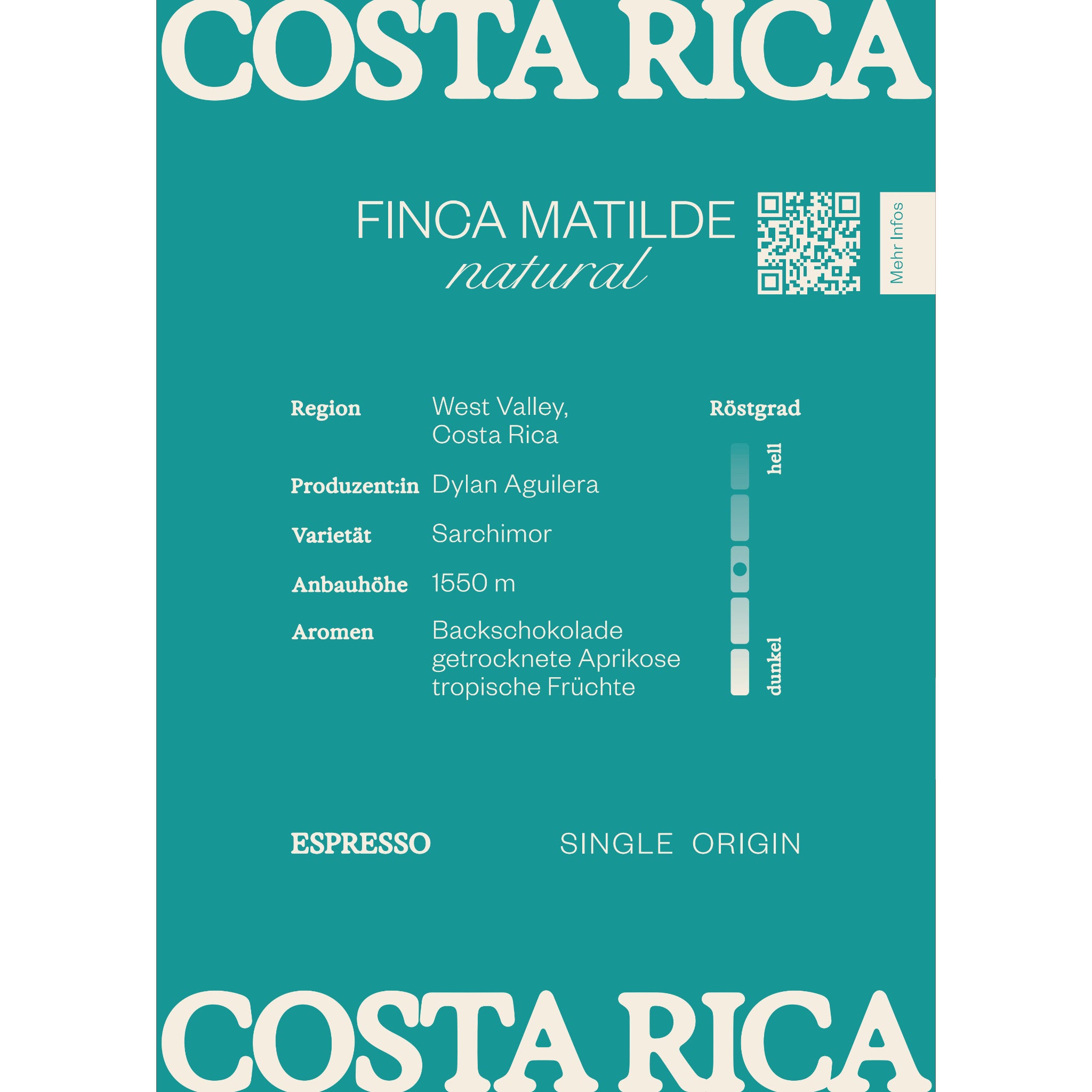

In regions with little rain and water scarcity, the “natural” treatment method is best suited. With natural processing, the coffee cherries are dried directly after sorting - including the pulp. To do this, the workers spread them out flat on large terraces or special coffee beds. They turn the cherries regularly and measure their moisture level. This ensures that they dry evenly and do not rot.

The bright red or yellow gradually gives way to a strong brown and then changes to a color that is reminiscent of raisins. In terms of taste, the natural processing promotes sweetness and fruity notes. A pronounced full-bodiedness is also characteristic. In contrast to other methods, the acidity tends to fade into the background with natural processing.

Our partner Cafe Imports has produced a great video series on different types of processing, which we link below.

What is washed coffee?

Washed processing is the most common form of coffee processing. The coffee cherries are put into so-called depulpers. These are machines that separate the pulp of the cherry from the beans.

And this is how it works: Ripe and unripe coffee cherries are pressed against a sieve in a rotating drum using centrifugal force. With the right pressure, the softer flesh (also called pulp) of the ripe cherries comes off and the beans pass through the sieve. The hard pulp of the unripe coffee cherries does not come off easily and therefore they remain in the drum of the machine.

Ferment coffee

To remove pulp residue, the coffee beans are fermented in a water tank. During the 24-72 hour fermentation, the fruit residues dissolve and can then be washed off. How long the beans have to stay in the tanks depends on external influences such as climate and altitude. Workers then dry the beans on terraces or coffee beds. If there is too much rain or too high humidity, drying by machine is also common.

In terms of taste, the washed preparation enhances the acidity and complexity of the coffee. Coffee fans appreciate washed coffee for its lightness and elegance.

What is Pulped Natural Coffee?

During pulped natural processing, coffee beans are separated from the pulp in the depulper. Unlike washed preparation, they are then dried directly - without being “washed off”. As a result, mucilage remains on the bean, which dries and affects the taste.

In terms of taste, pulped natural coffees lie somewhere between natural and washed coffee. The fruitiness and acidity are often described in comparison to natural or washed coffees. The coffees are often characterized by a clear sweetness .

What is Honey Coffee?

Honey processing works similarly to Pulped Natural processing. After the pulp in a depulper has been separated from the coffee bean, the beans are dried. The difference is that with honey processing, more pulp is left on the bean as it dries.

A distinction is made between the types White Honey, which is most similar to Pulped Natural, Yellow Honey, Orange Honey, Red Honey and Black Honey. The darker the color name, the more pulp remains on the bean to dry with it, giving off flavor.

In terms of taste, the sweetness and fruitiness increase the more pulp remains on the drying bean. The name Honey comes from the slippery, sweet, yellowish layer on the coffee bean that envelops it.

The Indonesian method: Wet-hull processing

Like many other coffee-growing countries, Indonesia has a very humid climate. In addition, coffee grows very quickly on the islands and should therefore be sold on as quickly as possible. In the Asian country, many coffee producers therefore rely on their own processing method. During wet-hulling , which is known as Giling Basah in Indonesia, the coffee cherries are removed from the beans immediately after harvesting. What remains is the mucilage layer and the parchment membrane of the bean.

The bean and its appendix are then fermented overnight in a water bath to soften the slimy pulp layer and then wash it off. Unlike the processing methods listed above, the beans with their parchment skin are now only dried to around 50% residual moisture - instead of 10-13%. This only takes a few hours instead of several weeks. The beans are then often sold directly to a processing company, where they are further dried to 25-35% residual moisture. Then the parchment membrane is removed. Since the bean is still very moist, it can be damaged during this process, which will later be visible in the bean image. In Indonesia they speak of a goat's foot .

Coffee preparation advanced

More modern methods of coffee preparation include anaerobic fermentation, the use of lactic acid bacteria and carbonic maceration. Compared to the above methods, modern processing is more complex. This particularly applies to the required equipment in the form of airtight pressure vessels made of stainless steel.

What does anaerobic mean in coffee?

For anaerobic fermentation, the beans are placed in an airtight tank. The previously removed pulp is added unless the whole cherry is fermented anyway. The tank is then freed of oxygen and sealed afterwards. Water is often used. Some of the pulp and its juice pass into the coffee beans. To ensure that alcohol is not produced, several parameters must be constantly and closely monitored. These include, for example, pH value, the pressure in the tank or the CO2 content.

The cherries or beans can then be processed (semi-)naturally or washed. In terms of taste, anaerobic fermentation manifests itself in a high level of complexity and a pronounced acidity. Rather simple coffees can be made more exciting and complex using fermentation technology.

What does Lactic Process mean in coffee?

In lactic processing, fermentation takes place in an airtight tank, like anaerobic fermentation. Lactic acid bacteria are added, which feed on the sugar in the coffee cherries and produce lactic acid.

In terms of taste, lactic acid manifests itself in unusual fruity and milky notes and a pronounced acidity.

What does carbonic maceration mean in coffee?

Carbonic maceration brings out the most unusual aromas in coffee processing. Carbonic Maceration Processing also uses an airtight tank in which the coffee beans ferment with added carbon dioxide. CO2 pushes the oxygen out of the tank via a valve and ensures that more tannins and anthocyanins come into the bean. The process comes from wine processing.

When it comes to taste, coffee fans report aromas of ripe berries, bananas and even chewing gum. However, these reports can hardly be generalized, after all, many parameters influence the taste of a coffee and the preparation is just one of them.

Decaffeination of coffee

There are various methods to remove caffeine from coffee beans, which we have explained in our article on decaffeinated coffee. What they all have in common is that the coffee to be decaffeinated is washed beforehand. You can read about how the decaffeination methods differ above by following the link.

Coffee processing overview

- The most common processing methods are Natural, Washed and Honey. They all have a significant influence on the taste of the bean.

- In natural processing, the entire fruit, i.e. coffee cherries and beans, is dried in the fresh air.

- During washed processing, the pulp is removed from the bean after harvest and fermented in tanks so that any pulp residue falls off completely.

- During honey processing, the pulp is only partially removed. Remains stick to the bean during drying and affect the taste.

- Modern processing methods include anaerobic fermentation and modifications with lactic acid bacteria or carbonic maceration of coffee.

2 comments

Nico | Günter Coffee

@Simon: Danke für deinen Kommentar und das Lob, ich habe den Teil entsprechend ergänzt. In der Regel kommt nach der Trocknung der natürlich aufbereiteten Kaffees eine sogenannte Dry Mill zum Einsatz, mit der das Fruchtfleisch und das Pergamenthäutchen der Kaffeebohnen entfernt werden.

@Simon: Danke für deinen Kommentar und das Lob, ich habe den Teil entsprechend ergänzt. In der Regel kommt nach der Trocknung der natürlich aufbereiteten Kaffees eine sogenannte Dry Mill zum Einsatz, mit der das Fruchtfleisch und das Pergamenthäutchen der Kaffeebohnen entfernt werden.

Simon

Vielen Dank für den Artikel – kompakt und sehr informativ! Beim Lesen ist mir allerdings eine Sache nicht klar geworden: Wie wird beim Natural dann schlussendlich das Fruchtfleisch von der Bohne getrennt? Vielleicht könnt ihr diese Information noch im Text ergänzen?

Vielen Dank für den Artikel – kompakt und sehr informativ! Beim Lesen ist mir allerdings eine Sache nicht klar geworden: Wie wird beim Natural dann schlussendlich das Fruchtfleisch von der Bohne getrennt? Vielleicht könnt ihr diese Information noch im Text ergänzen?