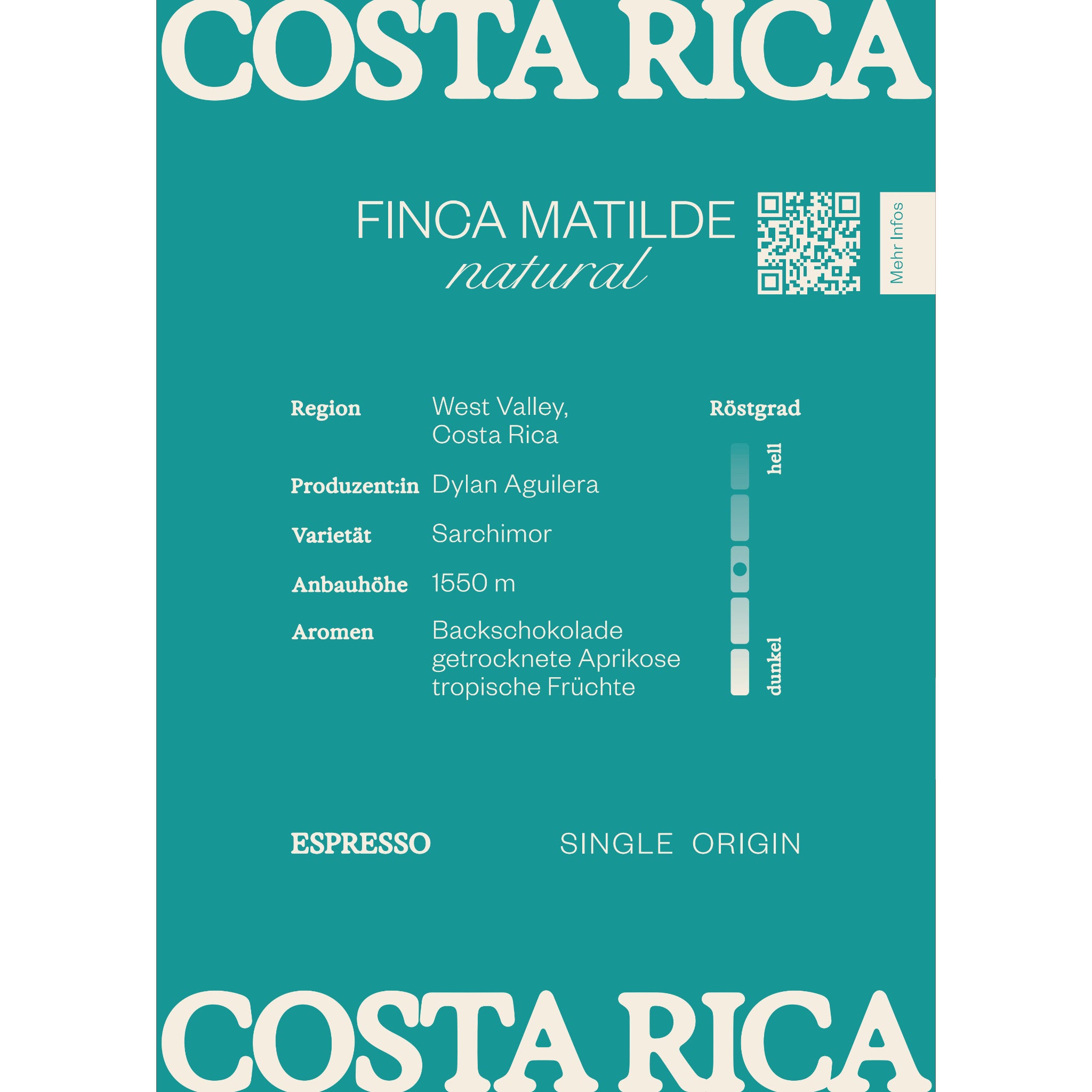

Coffee beans usually grow in pairs in a cherry tree and require a warm climate, which is found around the equator, in the so-called coffee belt. After harvesting and before roasting, usable beans are bluish-green, yellowish or brownish. Their color in their raw form depends largely on the method used to process them after harvesting. The coffee processing methods of the Honey family in particular result in yellow or even reddish green coffee beans, but decaffeination can also change the color significantly. The process for assessing the quality of these raw beans is still called green grading.

Farmers, buyers and roasters have an interest in the quality of the green coffee being as high and consistent as possible. The higher the quality, the more expensive the coffee can be sold and the better the taste potential. The quality requirements also depend on the intended use of the beans, for example in a roasted coffee blend or a single-origin coffee.

What is Green Grading?

Green Grading is the physical evaluation of green coffee, which precedes the sensory evaluation of roasted coffee. The quality and properties of coffee beans are examined to ensure that they meet the desired requirements. A representative sample of the beans, usually consisting of 350 grams, is examined and sorted according to various criteria:

- Size and shape: The beans should be of the same size and similar shape. The greater the differences, the more difficult it is to achieve a uniform roasting. There are various sieves with round holes for sorting by size.

- Color: The beans should have a uniform color and a good shine. There are various reasons for color differences, such as diseases of the coffee plant or underdeveloped beans.

- Density: The beans should have a uniform density. We'll explain how to determine this below.

- Humidity: The beans should have an optimal level of humidity. The Specialty Coffee Association has established a standard value of between 10 and 12%. If the beans are moister, they tend to develop mold more quickly. If they are drier, this will damage the aroma.

- Defects: The beans should be free of defects. These include, for example, insect damage, black beans, sour beans, burst or broken beans and a few more. Foreign bodies such as stones and the like are also included. Depending on the defect, these can damage the roasting machine and affect the quality of the end product.

- Smell: Green coffee beans should have a fresh, clean smell. A musty or moldy smell can indicate poor storage or contamination.

The Specialty Coffee Association defect scale

The Specialty Coffee Association, or SCA for short, has developed a defect scale that is used in green grading. The scale includes 13 types of defects that are divided into three categories. They play a key role in the assessment of coffee, and especially specialty coffee. For a coffee to be classified as specialty coffee, there must be no primary defects in the random 350-gram sample. There must be a maximum of 5 secondary defects, with the SCA referring to partial and full defects, which means that some defects may occur several times to be considered a full defect.

- Primary defects: These defects are serious and can significantly affect the taste of the coffee. In addition to completely black and completely sour beans, the SCA also lists fungal damage, foreign bodies, dried cherries and insect damage.

- Secondary defects: These defects are less serious, but can also have a significant impact on the taste of the coffee, especially if they occur frequently. The SCA lists partially black and sour beans as well as unripe, dried, broken and otherwise incomplete beans. These include parchment skins, floaters, dried coffee cherry shells and slight insect damage.

If green coffee is pre-sorted accordingly, many defects can be prevented. Specialty coffee is therefore primarily very well-sorted coffee that has a special flavor potential. This makes it a real luxury product compared to premium or lower quality grades that are also sold. This is why specialty green coffee is usually transported in so-called Grainpro sacks. These are plastic sacks that serve as a second protective layer against moisture, dirt and other influences inside the usual jute sacks.

| Primary defects | Incidents per defect | Secondary defects | Incidents per defect |

| Black beans | 1 | parchment | 2–3 |

| Fully sour beans | 1 | Cover/shell | 2–3 |

| Dried cherry | 1 | Broken/Cracked | 5 |

| Big stones | 2 | Insect damage | 2–5 |

| Medium-sized stones | 5 | Partially black beans | 2–3 |

| Big sticks | 2 | Partially sour beans | 2–3 |

| Medium sized sticks | 5 | Floater | 5 |

| Outer skin | 5 | ||

| Small stones | 1 | ||

| twigs | 1 | ||

| Water damage | 2–5 |

How to Green Grade?

Green grading is usually carried out by professionals who have acquired their skills either through training or years of daily professional practice. During green grading, the beans are first visually inspected for defects. The beans are then weighed and measured. The visual inspection looks at the size, shape, color, shine and moisture of the beans. The beans are also inspected for defects such as breakage, mold, insect infestation or other contamination.

The density of the coffee is determined by weighing and measuring the beans. This usually involves the bulk density, which is much easier to determine than the actual physical density of the green coffee. To determine the bulk density, the beans are filled into a container that has a volume of one liter, for example. The density for Arabica coffee beans, for example, is between 670 g and 750 g per liter. Ultimately, however, it depends on the exact variety of the bean. There are special electronic moisture meters to examine the moisture content of coffee beans.

Green Grading as part of the roasting championships

Every roastery and its roasting masters should understand something about green grading. On the one hand, because they should ensure that the beans they buy meet the quality promises. On the other hand, however, they also want to offer their customers the highest quality roasted coffee possible, both visually and in terms of taste. That is why green grading is also an integral part of the tasks of the participants in roasting championships and is included in the final score.