Although coffee is the most commonly consumed hot drink in Germany and elsewhere, people usually don't know anything about coffee cultivation and harvest. The explanation is simple: the coffee plant feels most comfortable in a tropical climate. However, there are some similarities to wine growing, which is better known in many European countries - including harvest.

Especially in the southern federal states of Germany, winemakers are happy about every helping hand during the grape harvest in September and October. Because wine and coffee are often grown on slopes, they have to be harvested manually. However, many wine and coffee farmers also consciously avoid using mechanical help. Here we will discuss why.

Coffee farmers harvesting coffee by picking.

The two coffee beans per fruit grow well protected in a so-called coffee cherry. These are actually seeds and not beans from which new coffee plants can be grown. Because of the visual similarity, the name bean has become established primarily in colloquial use.

Ripe coffee cherries can usually be recognized by their shimmering red tone, which immediately catches the eye. Then it's time for the coffee harvest. In addition to ripe cherries, unripe fruits and other things such as small branches and leaves are often thrown into the bucket, especially during manual stripping and mechanical harvesting.

Not all coffee cherries turn red, however. Varieties such as Yellow Catuai or Yellow Caturra have a strong yellow tone when ripe for harvest.

Coffee harvesting methods: picking, stripping, mechanical

When using the picking method, harvest workers only pick out the fruits that are at the right ripeness by hand. Unripe coffee cherries stay on the bush and overripe ones do too. The latter will eventually fall off on their own. For the unripe fruits, however, further harvest cycles take place over several weeks. By hand-picking the harvest, the coffee farmers ensure that the quality is consistently high, which is particularly important for specialty coffee.

Things are a little different with stripping, which hardly differs from mechanical harvesting except for the speed. Here the harvest workers grab a supporting branch on its top, wearing a glove. They close their hand and pull everything from the coffee plant. Between the cherries there are leaves, twigs and everything else that comes along with it.

The situation is roughly the same with mechanical harvesting, except that the cherries often remain on the bush. The huge machines drive along the coffee bushes wherever possible. Their shape is reminiscent of mobile, somewhat narrow car washes with fiberglass rods instead of textile brushes. They thresh the coffee bushes planted in a row to knock down or strip off the cherries. The coffee harvester then transports this and other material along a conveyor belt into a truck with a flatbed that drives alongside.

Coffee harvester on a farm in Brazil that Mats Weller visited in May 2022.

Harvest time for coffee

The coffee harvest usually lasts several months. The period is often divided into main and intermediate harvests. This is because the cherries on a plant do not ripen at the same time and because the coffee bushes are not planted all at once, but rather lot by lot. A coffee lot describes a piece of land on which several plants grow. This often involves one or two selected varieties. Each plant variety has a different fruit yield.

In the high altitudes of Colombia for example, the farmers from whom our friend Nikolai Fürst sources coffee with DDC, harvest from October to January and again in April and May. Vanía from Somaho tells us that the coffee harvest on Lake Kivu in Rwanda begins in February and lasts until June in the higher altitudes. This cannot really be generalized because the harvest is always heavily dependent on the weather.

During the main harvest season it is common to employ additional workers. Similar to the grape harvest, there is a lot more to do than usual.

Coffee harvest periods along the coffee belt

| January | February | March | April | May | June | July | August | September | October | November | December | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Angola | ||||||||||||

| Ethiopia | ||||||||||||

| Bolivia | ||||||||||||

| Brazil | ||||||||||||

| Burundi | ||||||||||||

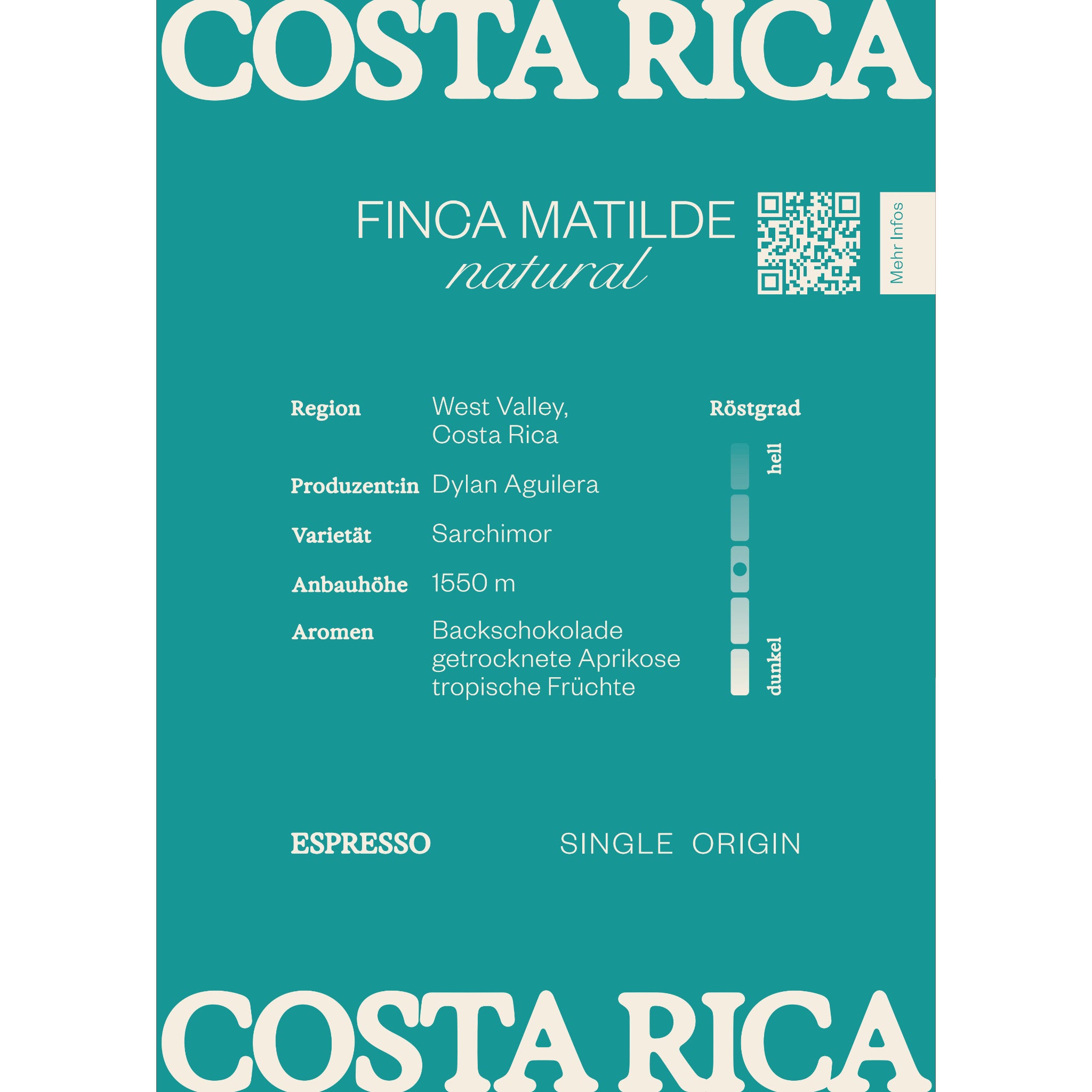

| Costa Rica | ||||||||||||

| Dominican Republic | ||||||||||||

| Ecuador | ||||||||||||

| El Salvador | ||||||||||||

| Guatemala | ||||||||||||

| Haiti | ||||||||||||

| Hawaii | ||||||||||||

| Honduras | ||||||||||||

| India | ||||||||||||

| Indonesia | ||||||||||||

| Jamaica | ||||||||||||

| Yemen | ||||||||||||

| Cameroon | ||||||||||||

| Kenya | ||||||||||||

| Colombia | ||||||||||||

| Congo | ||||||||||||

| Cuba | ||||||||||||

| Madagascar | ||||||||||||

| Malawi | ||||||||||||

| Mexico | ||||||||||||

| Nicaragua | ||||||||||||

| Panama | ||||||||||||

| Papua New Guinea | ||||||||||||

| Paraguay | ||||||||||||

| Peru | ||||||||||||

| Puerto Rico | ||||||||||||

| Rwanda | ||||||||||||

| Zambia | ||||||||||||

| Zimbabwe | ||||||||||||

| Tanzania | ||||||||||||

| Uganda | ||||||||||||

| Vietnam |

Sorting effort after the coffee harvest

Depending on the harvesting method, more or less sorting work is required afterwards. During manual picking, the workers make sure to only harvest ripe fruits before separating the coffee cherry from the plant. This means that the sorting effort is significantly lower than with stripping or mechanical harvesting.

But that doesn't mean there's nothing to sort through. People make mistakes and some defects are not even visible from the outside. That's why when harvesting through picking in the sorting process, here and there you'll find a twig, an over-ripe, under-ripe or a damaged fruit.

When stripping, the sorting effort is much higher. Because the supporting branches are stripped from top to bottom, there are a lot of unwanted things in the harvest. In addition to unripe or overripe coffee cherries, there are many small and medium-sized branches and leaves. The same applies to mechanical harvesting.

Sorting the coffee cherries

As with the harvest, there are also methods and machines developed for the first sorting that separate the unwanted from the ripe coffee cherries. The first sorting? Yes, because sorting is not only carried out immediately after the harvest, but also several times during further processing (Here you will learn more about coffee processing).

On the farms, fincas and fazendas where coffee is harvested by picking, the workers often sort the cherries by hand. For that, they spread them out evenly on tarpaulins.

Harvesting is not always possible or sensible by machine due to steep slopes and distributed coffee plants. Things look different when it comes to sorting. Once the coffee cherries have been picked and transported away, they can also be sorted easily by machine. As with grain, there are semi- and fully automatic machines that separate good cherries from bad ones. All kinds of conveyor belts, vibrating screens as well as camera, light and air pressure systems are used for this.

Sorting machine for freshly harvested coffee cherries on a farm in Brazil that Mats Weller visited in May 2022. Here floaters are separated from sinkers and stones and branches are sorted out.

However, higher levels of technology and automation are mainly found where coffee is grown industrially and where people can afford it. The more advanced the machines, the more expensive they are and the more coffee must be produced for the systems to be profitable.

Further processing of coffee cherries after initial sorting

When sorting by hand or automatic optical sorting with the help of camera systems, you can't look into the coffee cherry. A reliable way to detect internal defects in coffee cherries is a water bath. This separates floaters and sinkers.

Ripe and intact cherries, called sinkers, have a higher density than defective or overripe cherries, called floaters. That's why the latter float on the surface of the water, while the others sink to the bottom of the water bath.

Coffee harvesting overview

- The most common methods for harvesting coffee are picking, stripping and mechanical harvesting.

- During picking, workers selectively harvest the coffee cherries by hand.

- During stripping, all coffee cherries, i.e. ripe and unripe, are stripped from the branch.

- This is done either by hand or by machine.

- Harvesting by hand is often the only option, as coffee is often grown on slopes.

- The cherries are then sorted and freed from foreign bodies.

If you want to know more about processing coffee, read our article on processing green coffee .

2 comments

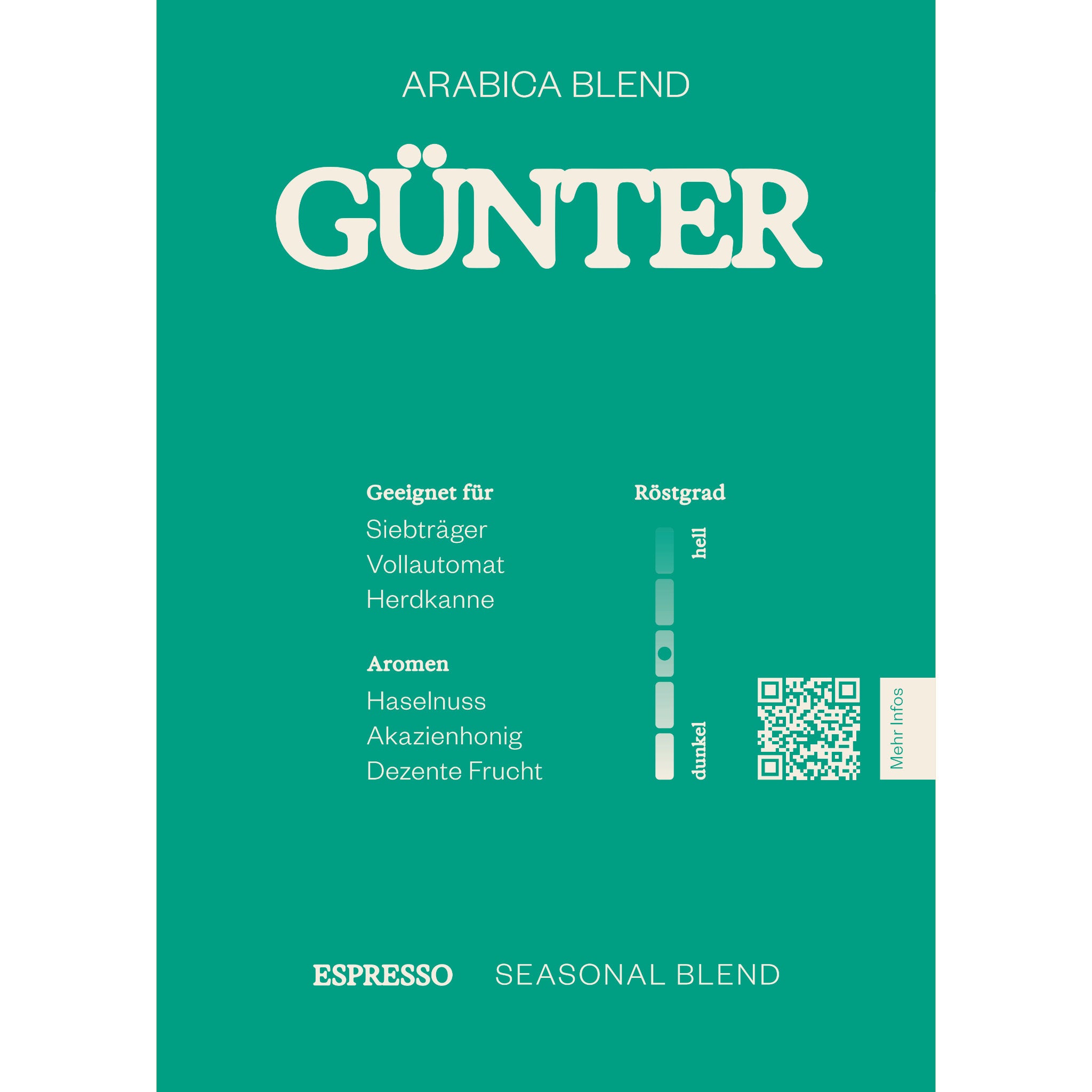

Nico | Günter Coffee

Maria Santer: Hallo Maria, den Artikel habe ich geschrieben, ebenso wie die anderen Artikel auf unserem Blog. Du erreichst mich unter nicoguentercoffee.com.

Maria Santer: Hallo Maria, den Artikel habe ich geschrieben, ebenso wie die anderen Artikel auf unserem Blog. Du erreichst mich unter nicoguentercoffee.com.

Maria Santer

Guten Tag

Ich wollte fragen, wer der Autor dieses Artikels “Wie wird Kaffee geerntet?” ist und wann der Artikel geschrieben wurde. Besten Dank schon im Voraus.

Gruss

Maria Santer

Guten Tag

Ich wollte fragen, wer der Autor dieses Artikels “Wie wird Kaffee geerntet?” ist und wann der Artikel geschrieben wurde. Besten Dank schon im Voraus.

Gruss

Maria Santer