Climate, soil conditions and varieties of coffee plants determine a large part of the aromas in your cup. Between the harvest and the roasting process, the chosen processing method is crucial for the taste.

When roasting, temperature and roasting time have a significant influence on the taste of the coffee. The two parameters can be used to precisely work out the sweetness, acidity and body of the coffee. The longer and hotter the green coffee is roasted, the more prominent are so-called roast aromas, which have nothing to do with the natural aromas of the original plant. That's why we tend to roast lighter than many coffee fans are used to. Those who dare to change habits rarely regret it. That's what we learn from our customers every day.

Find the right coffee beans

Coffee farmers can be found all along the coffee belt, which stretches around the equator. They grow a wide variety of types and varieties of the coffee plant. From Arabica to Robusta and from Bourbon to Yirgacheffe. The plants are as different as the countries in which they are cultivated. In order to find a suitable green coffee for our roasting range, we first have to test it. For this we usually order green coffee samples.

To find out whether they meet our expectations, we roast the green beans in small quantities. There are special miniature sample roasting machines for this: We use an Ikawa V2-Pro, which we fill with a maximum of 50 g of coffee beans for small test roasts. The high-tech device from England is in no way inferior to its larger counterparts in terms of information accuracy and precision. This means that the temperature and roasting time can always be precisely monitored and recorded. This is important in order to achieve consistent results even with a second, third and umpteenth roasting session.

The recording of the roasting process is called the roasting curve. Software interprets the information and displays it graphically on a screen. We use a program from Cropster for this.

Our sample roaster Ikawa V2-Pro in the cooling unit of our large Giesen W15A.

Now it's time for the first quality control of the test roasts. That's why we cup them. This means that we grind the coffee and then put the ground coffee into containers. We usually use small glasses for this and pour hot water into them without a filter. After the coffees have had time to steep, we break the crust of coffee grounds that has collected on the surface. The first test is always the smell test. We smell the coffee and its aromas.

To break the crust we use special cupping spoons . After the smell test, we skim off the coffee grounds. We then sip the coffee little by little using the spoons.

As a team, we assess the potential and quality of the samples. We decide together which of the roasts give the most harmonious overall impression. If none of the “cups” are convincing, it goes back to the Ikawa test roaster to roast more samples. If a bean is finally found that fits the range, it goes to the large roaster.

Develop and adapt the coffee roasting curve

We are currently roasting on our drum roaster from Giesen, which holds 15 kg. Larger roasters use machines that process several hundred kilos of coffee at once. No matter what machine and what capacity it is, the following always applies: test, test, and test again!

Thanks to the previous test roasts on the Ikawa, which looks like something out of a doll's house compared to the larger machines, we have indications for the appropriate final temperature and roasting time. The roasting curve itself cannot be adapted 1:1. When it comes to new roasting curves, our experience from previous roasts is the most important source of information. We also create an initial curve that matches the parameters of density, moisture and bean size of the green coffee. Another important question is whether we want to roast a filter coffee or an espresso.

When it comes to filter coffees, we tend to use lighter roasts with shorter roasting times. When it comes to espressos, we have to ask ourselves whether we want to offer the coffee as a single origin (pure) or in a blend and decide which components and characteristics we want to emphasize.

Philip monitors the development of a roasting curve live using the Cropster roasting software.

Various parameters play crucial roles in developing a roasting curve. For example, when roasters are talking shop, terms like first crack, development time, rate of rise (RoR) or final temperature can often be heard. These are therefore often found in the roasting curves and control panels of the roasting software. More on that later.

Roast coffee

To start, we put green coffee into the roaster's filling funnel. We then let it slide into the roasting drum via a flap as soon as the machine has reached the right temperature. Now it's time: full focus! The Giesen forwards all relevant information digitally to our roasting software. This presents the information graphically in the form of a temperature curve over time. Our roaster Philip can see directly when and where he needs to readjust to achieve the desired result.

The green coffee beans dance in circles in the roasting machine and are always in motion. The cycle is indicated by the set number of revolutions. This ensures that the beans are roasted evenly from the outer skin to the core without burning.

Philip presses the lever to pour green coffee from the hopper into the roasting drum. You can see the coffee beans dancing in the roaster through the observation window on the right.

The three roasting phases

The roasting process can be roughly divided into three phases. As with any abstraction, this classification is merely an aid and only describes the dominant events in the roasting process. Initially the beans mainly dry. They absorb energy in the form of heat and release water.

After the dry phase comes the Maillard phase. This is indicated visually by a change in the color of the beans. It is named after the French chemist Louis Camille Maillard, who first noted that the reaction of amino acids and sugars causes a color change. The third and final phase is the development phase, which begins after the ominous first crack.

During the roasting process, the color of the coffee beans changes from greenish to yellowish and finally brownish. This can be observed wonderfully through a small window in the drum. A large part of the water in the beans evaporates, which amounts to around 8-12% during storage. After roasting it is approx. 2.5%.

The heat in the roaster sets off all sorts of chemical reactions in the beans. This brings out the various natural flavors that make each coffee special and unique. However, during longer roasting processes, the natural aromas fade into the background in favor of heat-induced roasting aromas. We tend to use lighter roasts for most of our coffees. No two coffees taste the same and there are always new and interesting flavors to discover.

During roasting, the beans increase in size and lose weight at the same time. With our roasts the weight loss is between 11 and 15%. The longer the beans stay in the machine and the higher the roasting temperature, the lighter they become. Theoretically, until only ash remains. But this practically never happens; after all, it doesn't help anyone.

First crack and second crack when roasting coffee

In addition to the visually recognizable change, when we stand next to the roaster, we hear a small bang in the roaster from around 196 °C. The sound is similar to the “pop” we know from making popcorn. Suddenly escaping water vapor and CO2 from inside the coffee beans cause the auditory experience that roasting experts call the first crack.

Second cracks rarely occur. The reason: The cell structure of the coffee beans suffers considerable damage and the oils from the bean find their way to the surface. The coffee then quickly acquires a strong smoky or even charred taste.

After 9-13 minutes, the dance of the coffee beans in our roaster is over and we lead them through another flap into the cooling basin (depending on the amount of green coffee and the desired degree of roasting). A rotating fan keeps the roasted beans constantly moving. This means they cool down more quickly and there is no unwanted re-roasting, which would ruin the carefully monitored roasting process. After about 5 minutes, we then let the roasted coffee slide into a container for storage.

Philip uses the spectrometer to measure the color value of the coffee grounds. It's also about assessing the roasting and establishing consistency.

Cupping for quality control

Now it's back to cupping to assess the quality of the roasting curves. This happens every week in our roastery because we roast weekly. If a coffee tastes different than it should, we look for the cause. After all, something can always happen during roasting. In our roastery, for example, weather influences play a significant role due to the size of the room. How hot or cold is it? Is it raining or maybe storming? All of this influences the roasting process and must therefore be taken into account.

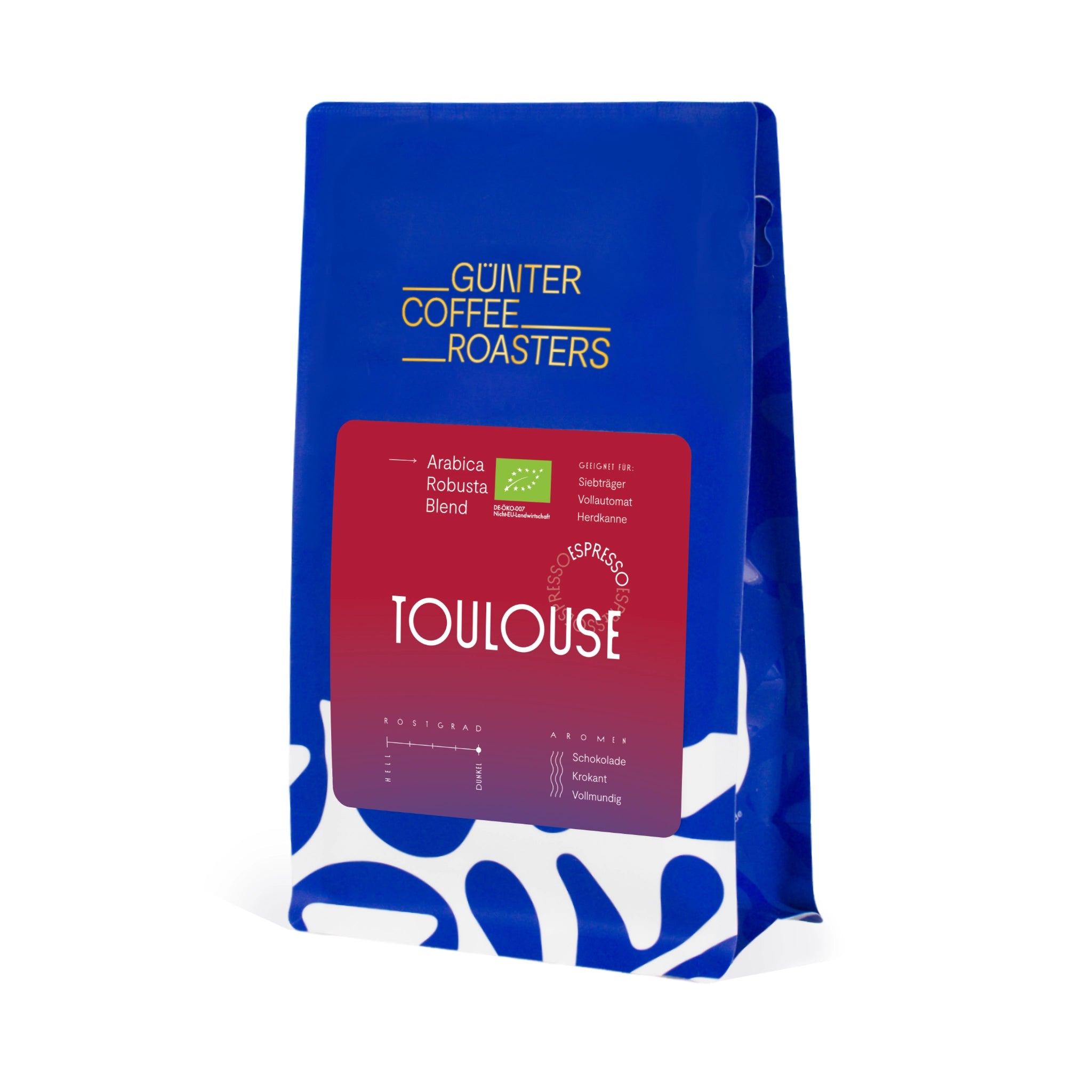

If the coffees meet our expectations, we store them for transport. Either in large white bins for our bulk buyers or in our bright blue bags to sell to our customers in the coffee online shop and locally.

Roasting level of coffee

The level of roasting indicates how light or dark coffee beans are roasted (scale of 5 from light to dark). The rule of thumb: the lighter the degree of roasting, the more of the bean's natural flavors are retained and come to light in your cup. The fruity origins of coffee becomes very clear.

However, the palate of most coffee drinkers is still used to strong roasted aromas . People often talk about Italian roasts. This means that the coffee beans are heated very strongly when roasting and you can taste it. This often involves roasting beyond the second crack.

We decided to cover a wide range of tastes. For our filter coffees we get a wide variety of aromas from the different coffee beans and for our stronger espresso roasts we pay attention to a balanced balance of roasted aromas and natural aromas. This opens up a whole new world of taste, from tangy-fruity to floral and tea-like to chocolatey-nutty.

This is why the roast date of coffee is important

The longer roasted coffee is stored, the more flavor it loses. (This especially applies to whole beans vs. ground coffee. Therefore: always grind freshly and brew within a few minutes!). At the same time, freshly roasted coffee is not ideal for immediate consumption. This is because it still outgasses after the roasting process. That's why our and many other coffee packets have a one-way valve that lets gas out but doesn't let oxygen in.

The following rules of thumb apply:

- Fresh espresso roasts should only be enjoyed 2-3 weeks after the roasting date. With filter coffee, a week is usually enough. Note: The lighter the roast, the shorter the waiting time.

- Espresso or dark roasted coffee tastes good for longer than lighter filter coffee, which should be consumed within three months.

Roasting coffee overview

- Before coffee is roasted, it is important to find suitable green coffee beans and test samples.

- Test roasting in small batches is the best and most sustainable way to experiment.

- Temperature and time play the main roles in the roasting process. The beans are heated to over 200 °C.

- The roasting process can be roughly divided into three phases: dry phase, Maillard phase and development phase.

- The longer the roasting process lasts, the more the roasting aromas usually predominate, gradually displacing the natural aromas of the coffee plant.